-

Lever punch, for cutting rubber and plastic material, samples, shapes, etc. Capacity up to 10kN. With this punching machine you can choose from a range of standard-compliant or customer-specific punching knives. The machine is equipped with a quick coupling system, which makes it easy to change the blades.

-

Cutting device for sample incision according to ISO 34 methods B and C.

-

Compact pneumatic sample die, for rubber and plastic materials. Capacity up to 25kN, for preparation of test samples in the laboratory. With this punching machine you can choose from a range of standard-compliant or customer-specific punching knives. The machine is equipped with a quick coupling system for the blades.

-

Airtight container for testing in liquids. This container is used in combination with the test frame EB 02 and is suitable for a pressure of up to 3 Bar. For example, samples in coolants can be tested under pressure. When testing in volatile substances, evaporation is prevented, reducing the risks of explosion. The container is equipped with a safety valve, which is set at approximately 3 Bar.

-

Temperature cabinet for testing in a standard ambient temperature of 23ºC, ±0.5ºC. Up to 4 test frames can be placed in the cabinet.

-

For stress relaxation tests in a temperature range up to 200 ° C, or optionally up to 300 ° C, the test frames are used in combination with the cell ovens. Options such as multiple samples in one temperature, as well as in different temperatures, are available. Various rigs for testing in pull and push force, and in air or in liquids.

-

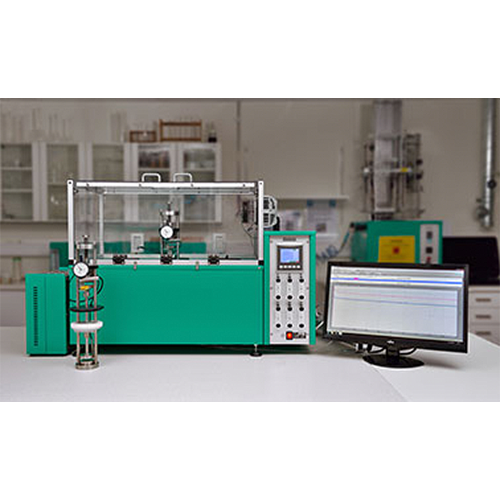

TR tester with automated test procedure. After cooling the liquid, the computer monitors the heating and measures the change in length of the samples. The result is displayed as TR10, TR30, TR50 and TR70. The result can also be shown in a table with length versus temperature. The test results can be exported to a spreadsheet for graphing. We recommend the use of an automatic liquid nitrogen cooling system.

-

Tube furnace, for determination of Carbon Black and ash content in polymers. This tube furnace is designed for material testing according to standardized test methods for rubber and plastics. The maximum temperature is 950 °C. Some characteristic specifications include overheating protection, a drying tube, flow meters, rinsing bottles and five quartz glass test tubes. This lightweight oven requires a workspace of W x D x H (mm) = 1350 x 275 x 355.

-

Genlab, cabinets for drying or heating glassware and instruments, blankets, electronics, etc. Range up to 70°C. Without insulation or with insulation for extra energy savings and improved efficiency. Available as standard non-insulated models and insulated versions, for better efficiency and cost savings. A touchscreen controller is also available as an option or upgrade on the isolated version.

-

Manufactured to the highest standards and packed with features and extras. As standard, the Prime range offers a mirror polished stainless steel interior and a temperature range of up to 100ºC. The touchscreen control offers intuitive operation, designed for laboratory incubators.

- Fluctuation +/- 0.15°C at 37°C

- Historical trend on the screen (48 hours)

- 8 Step Profile Check

- Count Down Timer

- 24/7 real-time clock control

- Increased ramp/recovery times

- Manual or automatic reset of the overheating

- High-precision Pt100A duplex sensors <0.6ºC

- Mechanical circulation

- Excellent stability <+/- 0.5ºC

- Excellent temperature uniformity

-

The GENLAB, Classic Series, offers a selection of highly efficient, reliable and cost effective furnaces for most drying, heating and general laboratory applications. The easy-to-use thermostat control is good for educational purposes and the stoves can be configured to suit individual requirements.