-

This cabinet oven for aging tests features excellent temperature stability and air distribution, which is controlled by the controlled airflow. The test oven is available in 60 and 120 liters. The EB 10-II is ideal for aging testing with finished products and large test samples, which are not suitable for testing in a cell oven. Both shelves and rods are included, so that practically all sample types can be tested.

-

Cette étuve de vieillaThis accelerated aging test oven has 4 compartments, the temperature of which can be individually controlled. Each compartment accommodates a sample holder for 24 test samples. This oven also complies with ISO 188 method A, IEC 811 and technically equivalent standards. This aging test oven offers test conditions with very low temperature variation in time and space, low air velocity and controlled air exchange rate.issement accéléré comporte 4 compartiments dont la température peut être contrôlée individuellement. Chaque compartiment accueille un porte-échantillon pour 24 échantillons de test. Ce four est également conforme à la norme ISO 188 méthode A, CEI 811 et aux normes techniquement équivalentes. Cette étuve de vieillissement offre des conditions de test avec une très faible variation de température dans le temps et dans l'espace, une faible vitesse d'air et un taux de renouvellement d'air maîtrisé.

-

Cell oven for life and aging testing of rubber and plastics in strictly controlled conditions. The EB 01 complies with the specifications described in the standards, ISO 188, ISO 3383, IEC 811 and technically equivalent standards. The EB 01 Cell oven has 4 cells with individually adjustable air exchange.

-

Cabinet oven, type EB 04-II, with aging test device. Meets the specifications of, ISO 188, IEC 811 and technically equivalent standards. This aging test oven offers test conditions such as very small temperature variation in time and space, low air velocity and controlled air exchange rate. For this, the oven is equipped with an inner chamber with a controlled air speed. The EB 04 is ideal for aging testing of finished products and large test samples, which do not fit in the cell ovens. Delivery includes shelves and rods for testing practically any type of sample.

-

Pressure test device. PC controlled, for stress relaxation measurements, specially designed for discontinuous measurements on rubber in accordance with ISO 3384 method B and standard pressure testing

-

Rubber aging tests in air and liquids.

Aging tests for rubber and elastomers. Large capacity, 3 samples can be tested in each of the 24 test tubes. High temperature accuracy Temperature range: + 40 ° C to + 200 ° C (EB 11) + 40 ° C to + 300 ° C (EB 11HT) A few features:- Aging tests in air and liquids.

- Temperature stability in time and space, ± 0.25 ° C

- Temperature control by sensor in test tube

- Temperature control accuracy, 0.1 ° C

- Power failure recording.

-

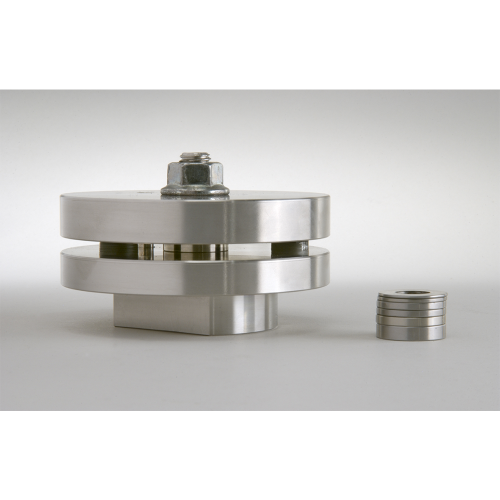

EV 03, compression set, according to ISO 815. The set consists of 2 round polished stainless steel discs with a central screw and spacer. Minimum number of components for easy sample placement. Spacers for large and small samples are included. A set of spacers from 1 to 20 mm in 0.5 mm steps is available as an option.

-

Easy and time-saving. During assembly of the samples for aging tests in a cell oven, this standard offers many advantages. Place the sample holder in the stand, and you have both hands free to place up to 24 samples.

-

Electrical resistance measurement according to ISO 2878. For conductive and antistatic rubber products. This instrument has a battery-powered megaohm meter, which measures test voltages from 250 VDC to 1000 VDC, using insulated stainless steel electrodes. Includes pen with conductive silver paint and 1 liter of conductive liquid.

-

Elongation test, according to ISO 2285. This stainless steel set can be set for 25% to 100% elongation and is easy to place in the sample holder of the cell ovens.

-

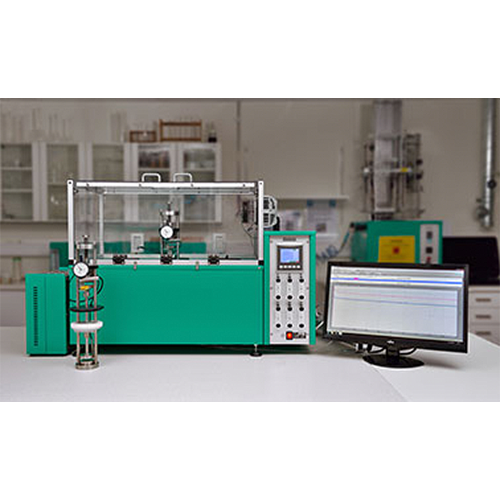

Gehman tester, computer controlled with 6 test stations. The Gehman test is performed according to ISO 1432, ASTM D1053 method A, or technically comparable standards. The computer monitors both the liquid heating and the measurement of the torsion angle of the samples. The results are graphed and the RM2, RM5, RM10 and RM100 values are calculated. The results can also be shown in a table. Vessels for storage of liquid nitrogen in the laboratory are available as an option.

-

Heat aging tests according to ISO 188 method B, and ISO 4577. Oven with high air speed and with a laminar air flow from bottom to top. An error of 1°C in temperature corresponds to approximately 10% error in test time, so temperature accuracy is very important for heat aging testing.

-

Heat aging testing of rubber in liquids and air This tube furnace has four compartments for simultaneous testing in different temperatures. Capacity, 6 test tubes per cell. High Temperature Accuracy Temperature range: + 40 °C to + 200 °C (EB 11) + 40 °C to + 300 °C (EB 11HT) A few features: Testing in liquids and air. Temperature stability in time and space, ± 0.25 °C Temperature control by sensor in test tube Temperature control accuracy, 0.1 °C Display in case of power failure.

-

Airtight container for testing in liquids. This container is used in combination with the test frame EB 02 and is suitable for a pressure of up to 3 Bar. For example, samples in coolants can be tested under pressure. When testing in volatile substances, evaporation is prevented, reducing the risks of explosion. The container is equipped with a safety valve, which is set at approximately 3 Bar.

-

Temperature cabinet for testing in a standard ambient temperature of 23ºC, ±0.5ºC. Up to 4 test frames can be placed in the cabinet.

-

For stress relaxation tests in a temperature range up to 200 ° C, or optionally up to 300 ° C, the test frames are used in combination with the cell ovens. Options such as multiple samples in one temperature, as well as in different temperatures, are available. Various rigs for testing in pull and push force, and in air or in liquids.

-

TR tester with automated test procedure. After cooling the liquid, the computer monitors the heating and measures the change in length of the samples. The result is displayed as TR10, TR30, TR50 and TR70. The result can also be shown in a table with length versus temperature. The test results can be exported to a spreadsheet for graphing. We recommend the use of an automatic liquid nitrogen cooling system.