-

Falling dart impact test. A traditional method for evaluating the penetration resistance and toughness of a plastic film. This test uses a bullet-shaped drop body that falls from a specified height onto the sample material. During the test, the weight of the falling body is increased. The test results can be used for quality control or evaluation of material behavior in field use.

-

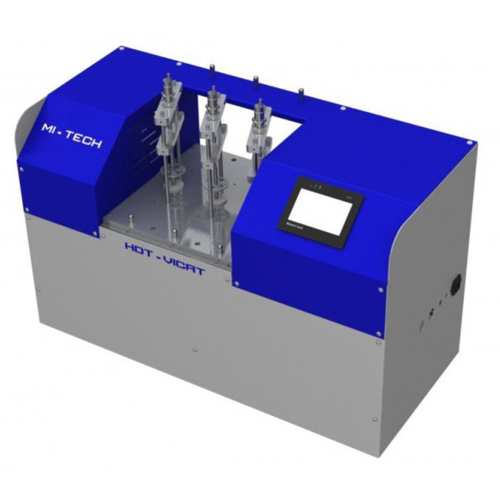

The HDT-Vicat tester is designed for simple and independent testing of plastics, according to the mentioned standards. Operation requires little training. The device allows the measurement of changes in the stiffness of a material (polymer, composite, ...) at elevated temperature levels. Also the performance of different materials can be compared on criteria of the mechanical strength of the temperature. This instrument is primarily an instrument of control, performing HDT or Vicat tests, simply by changing some accessories.

-

This economically priced Melt Flow Index Tester provides a complete solution for quick and easy determination of Melt Volume Rate and Melt Flow Rate, procedure A and B in accordance with ISO 1133 and ASTM D 1238 and comparable standards. Ideally suited for quality control in production environment, on raw materials, recycled products, etc.

-

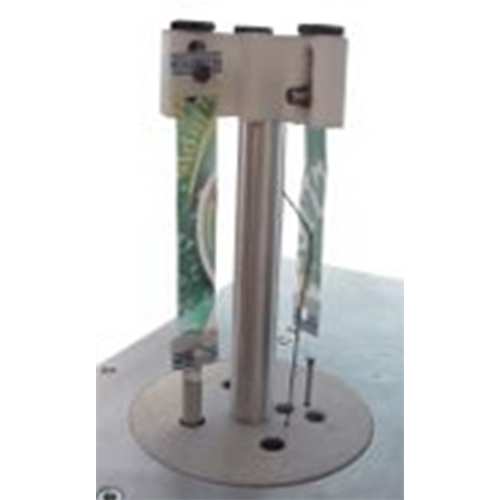

Retratech, for a complete characterization of the processing properties of thermal shrink film, strength and percentage of shrinkage (PE, PET, PVC, PP, etc.) The Retratech is used by producers of plastics and shrink film and by large consumers of shrink film. The Retratech is available with 2 or 4 test stations.

-

The Coup Test has been developed for testing the cut resistance on safety clothing, e.g. work gloves, in accordance with the standard EN 388:2016. In addition, it can also be used for R&D purposes on other products or materials. The design of the Couptest has recently been updated to meet the latest requirements regarding safety, ergonomics and the reproducibility of the test results.