-

The ABREX® simulates the testing of wear, by hand use or hand contact, on coating and printing of products, regardless of their shape, structure or material (plastic, metal, leather, etc.). The ABREX® simulates force and contact angle, in combination with standardized test materials and liquids, but also hand creams, lotions, (artificial) perspiration, cleaning agents, etc. The ABREX® offers the possibility to simulate, for example, the complex viscoelastic methodology of hand use, including chemical reactions. https://youtu.be/p9PBLnsv3hY

-

TAPERADER® is a mobile measuring instrument that provides real-time, reproducible measurement results of the wear resistance of surfaces through a method known as micro-grinding. This pocket-sized tribometer (TAPERADER) can be used almost anywhere and provides fast and accurate assessment of: Material surface coatings paint systems etc. the TAPERADER, tribometer, offers two measuring methods: A wear operation in the µm range is performed over a configurable measurement period from 60 to 20 s, and is recorded and immediately displayed as an a nm value. Determining the time in which, for example, a wear depth of 2 µm is reached, and displayed as a result.

-

The TRACEiT® measures 3-D topography, roughness values, Ra opt, Rq opt, Rz opt, and documents the visual perceptions as seen by the human eye. A patented and portable system for non-contact and high-quality measurements and analyzes of surfaces, both on outdoor locations and in the production line. TRACEiT® is the first system in the market with which visual impressions and external characteristics can be reproducibly evaluated, analyzed and documented.

-

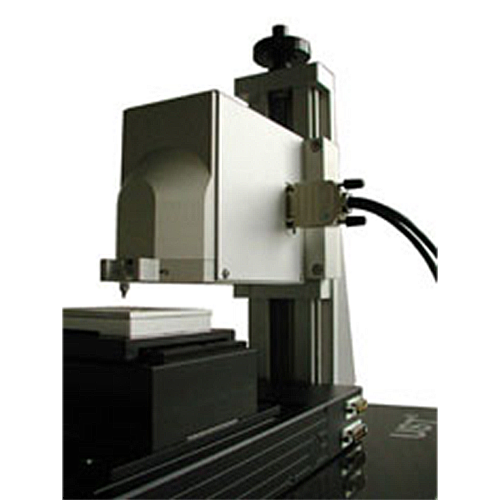

Universal instrument for the determination of micro-mechanical properties of materials and surfaces. Analysis with sub-micrometer accuracy of the micro-mechanics, micro-tribologic and functional properties of materials. Determinations of wear, scratch resistance, micro-friction, structure and haptic properties. The scope of application of the UST® is not limited to just plastics, paints, coatings and prints. Instead, metal, ceramics, textiles, rubber and in medicine, for example, human material, have also been carefully measured, evaluated and classified