-

Thermal conductivity range: 0.01 to 500 W / mK Thermal diffusivity range: 0.01 to 300mm² / s The system includes: - Trident Thermal Property Analyzer Electronic Control Unit - Standard Laptop with Windows 10® Operating System - Small Volume Test Cell - Pelican ™ Transport case - C-Therm TC3 ™ Software License Modified Transient Plane Source 1 × MTPS Sensor - Thermal conductivity: 0.01 to 500 W / mK (Max-k) - Temperature: -50ºC to 200ºC (optional up to 500ºC) - Test materials: solids, liquids, powders, pastes Reference Material: Expanded Polystyrene (EPS), LAF6720, Pyrex, Pyroceram, Phosphate Bronze, Copper Transient Plane Source 3 × Flex TPS (hot disc) Kapton based sensors - Thermal conductivity: 0.03 to 500 W / mK - Temperature: -50ºC to 80ºC (optional up to 300ºC) Reference material: stainless steel 304 (x2) Transient Line Source 1 × 150mm TLS Needle Probe - Thermal conductivity: 0.1 to 6 W / mK - Temperature: -55ºC to 200ºC - Test material: viscous / viscous liquids, non-consolidated solids, molten polymers Reference material: Glycerine Climate cabinet is available separately.

-

The C-Therm Tx uses the patented Modified Transient Plane Source (MTPS) technology. The one-sided heat sensor applies an instantaneous constant heat source to the sample. Thermal conductivity and effusivity are measured directly, providing a detailed overview of the thermal properties of the sample.

-

Fogging test according to ISO 6452, ASTM D5393, DIN, VOLVO, and other specific standards for fogging testing. This compact device has a cooling and heating bath in one housing. There is a choice of two cooling systems: EB 03, Tap water cooling, the water temperature must not exceed 18°C for this. EB 03C, Built-in Peltier cooling elements The EB 03 comes with a standard package of accessories. A complete overview of these and the optional accessories can be found in the brochure.

-

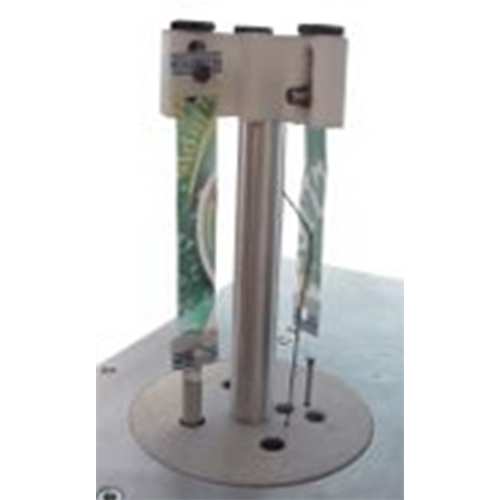

This Hot Set Tester provides standard conditions for performing hot set tests on the cable sheath material according to IEC 811-2-1. Temperature loss is limited by introducing the samples through a small opening in the top of the oven. The sample holder is placed at working height and the servomotor driven screw system takes the samples in and out of the oven. With the adjustable flow meter, the number of air changes and the low air speed are set, according to the specifications for aging ovens as in the standard IEC 811. The measurements are made with a laser pointer on a measuring scale mounted in front of the window window. The window can be disassembled for cleaning. By means of a push button, the strain measurements are registered and transferred to a template in Excel. The hot set value is measured outside the oven with a digital caliper and also exported to the Excel template. The test report can then also be created in Excel. The delivery of the Hot Set Tester includes the computer and clamps and weights for 8 samples.

-

Tube furnace, for determination of Carbon Black and ash content in polymers. This tube furnace is designed for material testing according to standardized test methods for rubber and plastics. The maximum temperature is 950 °C. Some characteristic specifications include overheating protection, a drying tube, flow meters, rinsing bottles and five quartz glass test tubes. This lightweight oven requires a workspace of W x D x H (mm) = 1350 x 275 x 355.

-

This economically priced Melt Flow Index Tester provides a complete solution for quick and easy determination of Melt Volume Rate and Melt Flow Rate, procedure A and B in accordance with ISO 1133 and ASTM D 1238 and comparable standards. Ideally suited for quality control in production environment, on raw materials, recycled products, etc.

-

Retratech, for a complete characterization of the processing properties of thermal shrink film, strength and percentage of shrinkage (PE, PET, PVC, PP, etc.) The Retratech is used by producers of plastics and shrink film and by large consumers of shrink film. The Retratech is available with 2 or 4 test stations.