-

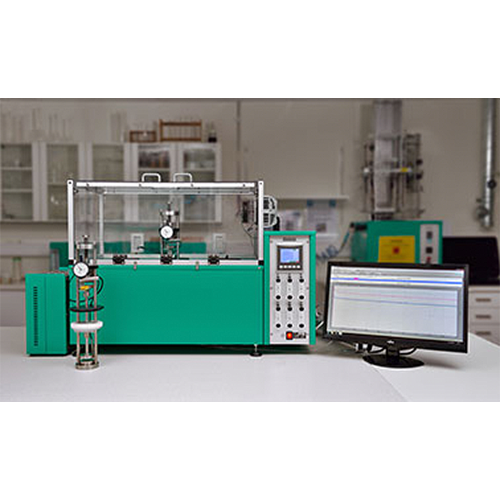

Pressure test device. PC controlled, for stress relaxation measurements, specially designed for discontinuous measurements on rubber in accordance with ISO 3384 method B and standard pressure testing

-

A range of standard-compliant or customer-specific dies. Available with a suitable coupling for our die-cutting machines, type EP 02 and EP 08, or your own die-cutting machine of any other brand. The blades are made of hardened steel and have a spring-loaded ejector mechanism. A guarantee for a perfect standard-compliant cutting quality and an efficient preparation of your test samples.

-

Drilling tools for cutting test pieces for pressure and wear tests. The blades are made of hardened steel. They are placed in a stationary drill and used in combination with a soft cutting substrate and ethanol or propanol as a lubricant.

-

Easy and time-saving. During assembly of the samples for aging tests in a cell oven, this standard offers many advantages. Place the sample holder in the stand, and you have both hands free to place up to 24 samples.

-

Electrical resistance measurement according to ISO 2878. For conductive and antistatic rubber products. This instrument has a battery-powered megaohm meter, which measures test voltages from 250 VDC to 1000 VDC, using insulated stainless steel electrodes. Includes pen with conductive silver paint and 1 liter of conductive liquid.

-

Fogging test according to ISO 6452, ASTM D5393, DIN, VOLVO, and other specific standards for fogging testing. This compact device has a cooling and heating bath in one housing. There is a choice of two cooling systems: EB 03, Tap water cooling, the water temperature must not exceed 18°C for this. EB 03C, Built-in Peltier cooling elements The EB 03 comes with a standard package of accessories. A complete overview of these and the optional accessories can be found in the brochure.

-

Gehman tester, computer controlled with 6 test stations. The Gehman test is performed according to ISO 1432, ASTM D1053 method A, or technically comparable standards. The computer monitors both the liquid heating and the measurement of the torsion angle of the samples. The results are graphed and the RM2, RM5, RM10 and RM100 values are calculated. The results can also be shown in a table. Vessels for storage of liquid nitrogen in the laboratory are available as an option.

-

Heat aging tests according to ISO 188 method B, and ISO 4577. Oven with high air speed and with a laminar air flow from bottom to top. An error of 1°C in temperature corresponds to approximately 10% error in test time, so temperature accuracy is very important for heat aging testing.

-

This Hot Set Tester provides standard conditions for performing hot set tests on the cable sheath material according to IEC 811-2-1. Temperature loss is limited by introducing the samples through a small opening in the top of the oven. The sample holder is placed at working height and the servomotor driven screw system takes the samples in and out of the oven. With the adjustable flow meter, the number of air changes and the low air speed are set, according to the specifications for aging ovens as in the standard IEC 811. The measurements are made with a laser pointer on a measuring scale mounted in front of the window window. The window can be disassembled for cleaning. By means of a push button, the strain measurements are registered and transferred to a template in Excel. The hot set value is measured outside the oven with a digital caliper and also exported to the Excel template. The test report can then also be created in Excel. The delivery of the Hot Set Tester includes the computer and clamps and weights for 8 samples.

-

Lever punch, for cutting rubber and plastic material, samples, shapes, etc. Capacity up to 10kN. With this punching machine you can choose from a range of standard-compliant or customer-specific punching knives. The machine is equipped with a quick coupling system, which makes it easy to change the blades.

-

Cutting device for sample incision according to ISO 34 methods B and C.

-

Compact pneumatic sample die, for rubber and plastic materials. Capacity up to 25kN, for preparation of test samples in the laboratory. With this punching machine you can choose from a range of standard-compliant or customer-specific punching knives. The machine is equipped with a quick coupling system for the blades.

-

For stress relaxation tests in a temperature range up to 200 ° C, or optionally up to 300 ° C, the test frames are used in combination with the cell ovens. Options such as multiple samples in one temperature, as well as in different temperatures, are available. Various rigs for testing in pull and push force, and in air or in liquids.

-

TR tester with automated test procedure. After cooling the liquid, the computer monitors the heating and measures the change in length of the samples. The result is displayed as TR10, TR30, TR50 and TR70. The result can also be shown in a table with length versus temperature. The test results can be exported to a spreadsheet for graphing. We recommend the use of an automatic liquid nitrogen cooling system.

-

Tube furnace, for determination of Carbon Black and ash content in polymers. This tube furnace is designed for material testing according to standardized test methods for rubber and plastics. The maximum temperature is 950 °C. Some characteristic specifications include overheating protection, a drying tube, flow meters, rinsing bottles and five quartz glass test tubes. This lightweight oven requires a workspace of W x D x H (mm) = 1350 x 275 x 355.

-

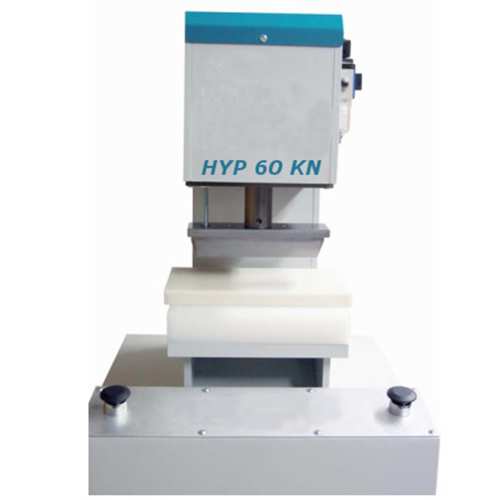

HYP XX, A series of compact hydraulic punching machines, executed in a solid casting construction, capacity up to 100kN. These easy-to-operate die cutting machines are ideally suited for cutting test and material samples. Applications include metal, rubber, plastics, leather, and components for electrical or toy products.

-

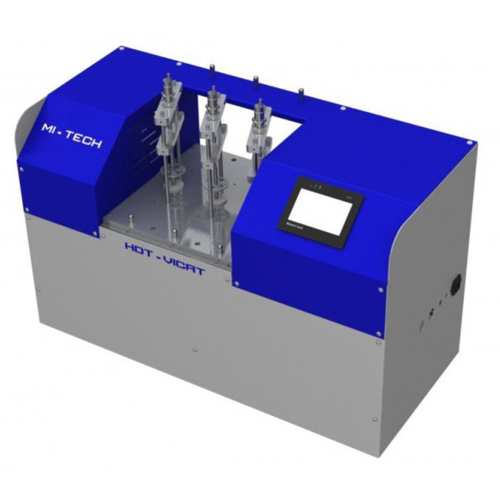

The HDT-Vicat tester is designed for simple and independent testing of plastics, according to the mentioned standards. Operation requires little training. The device allows the measurement of changes in the stiffness of a material (polymer, composite, ...) at elevated temperature levels. Also the performance of different materials can be compared on criteria of the mechanical strength of the temperature. This instrument is primarily an instrument of control, performing HDT or Vicat tests, simply by changing some accessories.