-

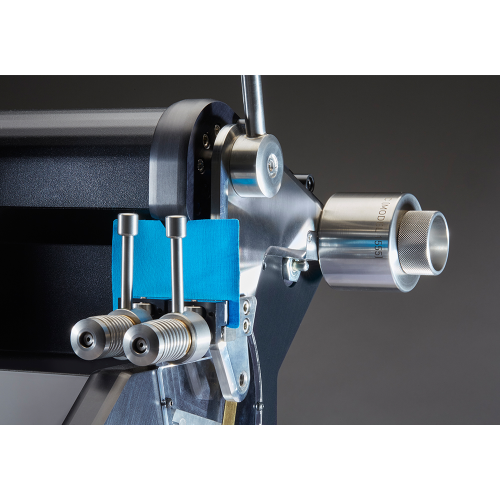

The AquAbrasion is an accurate and repeatable way to perform wet wear testing, which we have proven to be a critical and often damaging step in determining the durability of outdoor wear. Deionized water can be used to replicate rain, or a sweat solution can be used to replicate sweat. Fabrics exposed to wet conditions are found to wear more strongly than when subjected to the same abrasive stresses under dry conditions circumstances.

-

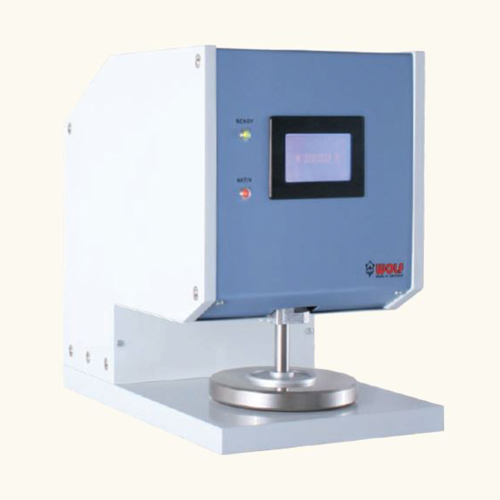

Crack test, digital Elmendorf. Versatile and powerful. Meets all standards for tear testing of textiles, paper, non-woven and plastic film and foil. This Elmendorf, has a contemporary styling and offers a wide range of new functions that offer real advantages, such as reliable test results, high accuracy, safety and flexibility.

-

The test results are clearly displayed on the built-in control panel. This panel shows all essential test parameters, such as the test speed, the force and the load. QuickTest can be set to automatically return to the starting position. This makes it easy to program repeats. This feature reduces setup time, giving operators the ability to run the same test cycle a total of 9999 times before having to re-enter settings.

-

Specially designed for testing textiles, non-woven and leather in various forms: yarns, fabrics, clothing and the safety of accessories. The combination of technical innovation and intuitive contributions from users has led to the realization of this user-friendly test device. With the intelligent and easy to use "TestWise" software you can get started with 3 clicks. The extensive library of test routines, together with the wide variety of clamps and grippers, make it possible to test according to a large number of international and customer-specific standards. A few features: Wide range of clamping tools for custom and standard test routines Rapid change of clamping pieces and power cells Testwise software with an extensive file of pre-programmed test methods

-

Burst pressure and material fatigue tester. Including the functionality of 3D material fatigue, fully pneumatically controlled. Exceeds the standard specifications of ISO 13.938-2, ASTM D3786 and many other national and international standards. The distinctive flexibility of this burst pressure testing device provides the ability to test a wide variety of materials including textiles, nonwovens, paper, cardboard, plastics and medical products.

-

WickView is a state-of-the-art measuring instrument for tracking and registering moisture transport in a garment. The advanced imaging system provides a good picture of moisture absorption and drainage, and as such, the effectiveness of these properties in a garment can be determined. The ability to rotate samples in both vertical and horizontal position faithfully simulates the wearing of clothing on the body.

-

Elmendorf tester. Test device for tear resistance of paper, textile, film, foil. Microprocessor controlled, with digital display. According to the Elmendorf test method, up to a pendulum impact force of 30,000 cN, for e.g. geotextiles, fiber reinforced materials. Option: LABODATA III software program.

-

Also for mouth masks tests according to EN 14683, appendix C. Recently adapted for the fully automatic course of this test. Also for technical textiles. Can be used in the laboratory and the production process. Textest has established itself worldwide with its air permeability measuring equipment. Already 50 years of experience, know-how and development in measurement of air permeability is the basis for this. The Multi-functional Labair IV meets all requirements when it comes to the air permeability of your products.

-

Also for mouth caps testing according to EN 14683, Annex C. The calculation (pressure drop in Pa divided by 4.9) must be performed manually. The Textest, MinAir, for measurements of air permeability and pressure drop. For use as a lab device but also for measurements on location. The Minair operates in accordance with ASTM D 737, DIN 53887, EN ISO 9237, WSP 70.1 and many other national and international testing standards.

-

The Portair is the first and only portable instrument for point or profile measurement of air permeability. Special Features: Wide measuring range. AP: approx. 0.2-1,000 ft³/ft²/min (approx. 1-5,000 l/m²/s), thickness: 0-6mm. The instrument is suitable for both spot and profile measurements. High measurement accuracy High measuring speed up to 200 m / min. (!) High resolution of up to 1mm test point pitch. Lightweight portable instrument, suitable for one-handed operation, even overhead. Touch screen for digital and graphical display of test results. One of a kind worldwide. Operates to all leading testing standards. Calibratable.

-

EN 16603, EN 16604, ASTM F 1670 and ASTM F 1671. Newly developed due to the high demand for testing according to the above standards. With this new instrument, up to six penetration cells can be connected simultaneously. The pressure sequences can be selected according to the standards or they can be freely programmed. In addition, a 100 cm2 test head can be added to perform regular water column tests up to 500 mbar.

-

Measurement of the resistance to permeation of liquids in materials, eg textiles, nonwovens and films (with and without coating). This water column test is easy to perform and provides accurate, reproducible information about the permeability of your materials. Three tests, the dynamic, static and program test mode. Your choice: manual, semi-automatic or - unique worldwide: - fully automatic test procedure without the presence of the operator. Choice between three models: FX 3000-4L PUM, test pressure up to 500 mbar (5 m water column) with built-in pump and mechanical sample clamp. FX 3000-4M, test pressure up to 2,000 mbar (20 m water column) with external compressed air connection and pneumatic sample clamp. FX 3000-4H, test pressure up to 5,000 mbar (50 m water column) with external compressed air connection and pneumatic sample clamp. Characteristic features: Time-saving features, such as adjustable alarm value, automatic program flow during "pass/fail" tests and an optional automatic drop detector. Well lit test area with unobstructed view of the test sample. Quick and easy clamping of the test sample. Touch screen operation with digital and graphic display of the test results and the test sequence. Data transfer: via USB, Ethernet Operates in accordance with all major testing standards. Calibratable. Options: Automatic water level control WLAN for direct access to the network. Integrated software for evaluation and storage of test results in XML format. Integrated strip printer for printing a test report.

-

This thickness measuring device has been used in laboratories all over the world for decades. The depth of measurement, foot shape and test pressure are configured to test materials in accordance with the respective specifications of the applicable ISO, EN and DIN standards. This hand-held thickness gauge has an interface for digital processing of the measurement data.

-

The specifications of this thickness gauge are the same as the DM 2005. The exception is the manually operated foot movement instead of a motor-driven transport. The stability of the speed of the foot movement is controlled by a delay in the transmission of the control lever.

-

Alternative to the thickness measuring device, DM 2010. Equipped with a measuring unit with LCD, instead of the illuminated, menu-driven touch-screen. This thickness gauge has a segmented display and individual control keys. Of course there is a data output for the digital processing of the measurement results. The DM 2005 model is also available with the options: - Adjustable measuring time - Selectable measuring range

-

Thickness measuring device, standard compliant for various materials. Measuring range optionally up to 10 mm, 25 mm or 50 mm.

- Resolution of your choice, 0.001 or 0.01 mm

- Measuring depth (center of base) 110 mm

- Illuminated graphic touch screen. Menu-driven operation (optionally in German or English)

- Single measurements and measurement series with adjustable number of measurement cycles

- Always up-to-date and simultaneous display of measured value, measuring cycle, mean and standard deviation

- Automatic zero point control

- Adjustable measuring time, from 1 - 60 seconds

- Motor driven constant speed foot movement. (standard 2.5 mm / s)

- Time-saving pre-settable measuring path

- Digital interface

- Footswitch operation

- Software

-

This thickness measuring device combines all the functions of the DM 2010, with the automatic transport of the sample material. The transport speed and sample length are adjustable.